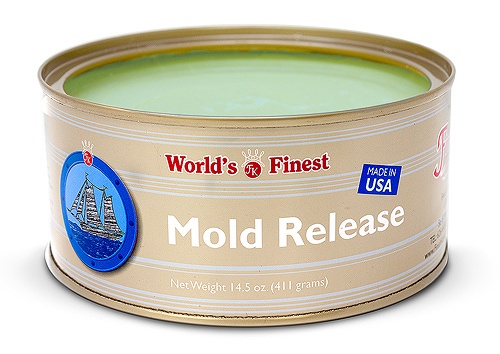

- Contains a blend of synthetic waxes and is one of FK’s premium mold release waxes.

- Proper application of this wax will result in a film that has high gloss and has resistance to intensive wear, heat and water.

- Good for up to 275º F or 135º C.

-

-

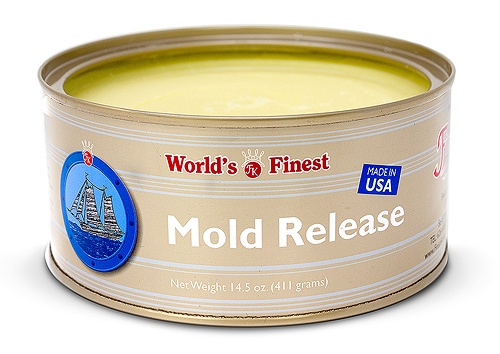

- True high-gloss paste wax.

- Withstands high-temperature exothermic reactions of resins and does multiple releases easily.

- Contains carnauba wax, synthetic waxes and high-temperature resistant resins for effective multiple releases of plastic parts through numerous cycles.

- Good for up to 230º F or 110º C.

- Buttery texture provides easy on/off applications.

- Sets up faster and harder and assures quick, clean releases without wax buildup or transfer.

- Recommended for the effective release of any FRP or cultured marble parts, polyesters, polyurethane, etc....

-

- As the name implies, designed to withstand higher temperatures and is harder than other waxes.

- Good for up to 275º F or 135º C.

- USAGE: Higher temperature exothermic reactions.

-

- Specially designed to reduce the slip factor, which under some situations might allude to pre-release.

- In the event “pre-release” occurs on corners, wells and radiuses due to excessive exothermic heat generated by mass chopping over these areas due to repeated passes, apply #1006 as the last coat or last two coats over the application of #1000P prior to gel coat and lay up.

-

- Specially designed for use between multiple releases to relieve the wax build up and reduce surface tension in molds.

- Helps to prolong the life of multiple cycle releases.

- Solvents in the product liquefy the mold release waxes to form an even coat on the mold for easy de-molding.

-

- Formulated so as to be brushed over gel coat before the final wax coat is applied without worrying about fish eye.

- Recommended to be applied to any mold surface, whole or partial, where brushing the gel coat on the mold is required.

- Can be used over #1000P as the final coat or used by itself when gel coating.

-

- Solvent-based mold cleaner for removing wax.

- Contains toluene and fortified with polymers.

- A much stronger cleaner than #69 that can be used for the clean-up of all types of molds prior to applying porosity sealing agents and mold release agents – wax-based or otherwise.

- Apply at least 2 coats of #135-80 for proper cleaning of molds and assured releases.

-

- Heavy-duty (HD) cousin of FK’s #332: Hand or Spray Interphase Release Wax. Contains the same high-melt synthetic blend waxes incorporated into #1000P: Hi-Low Paste Wax and #1000L: Hi-Low Liquid Wax but the solvent systems have been changed to reduce viscosity and make the product sprayable.

- Field tested and fully embraced by all users because it gets the job done – especially for larger molds, panels and other large jobs that require excessive labor for application of paste or liquid waxes.

- Very easy application – just spray on, allow it to dry and then wipe lightly – quick and easy. Cuts your labor costs and increases your productivity.

-

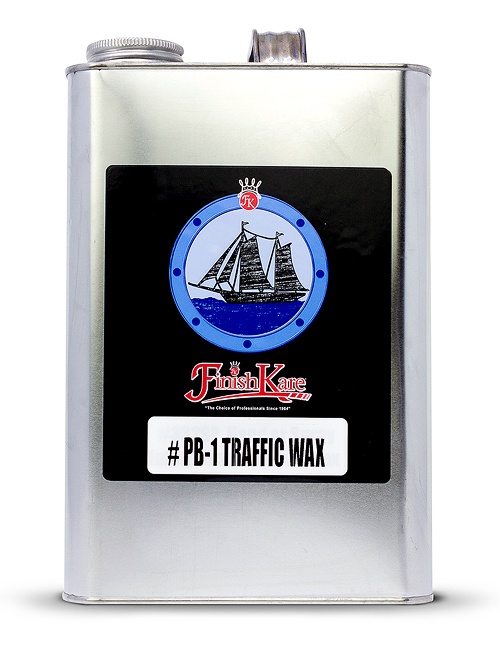

- Can be mopped or wiped on. Reduces clean-up time and increases efficiency in production.

- Eliminates fire hazard by removing the use of paper.

- One gallon of #PB-1 will cover approximately 150-200 square feet on porous surface and up to 400 square feet on smooth non-porous surface.

- Recommend using three applications; Allow each coat to dry prior to applying the next coat – assuring proper coverage.cations; Allow each coat to dry prior to applying the next coat – assuring proper coverage.

-

- A polymer solution designed for efficient "sealing of porosity" in new and rejuvenated molds.

- Aids and assists the wax release agents to assure a clean and easy demolding.

-

- Specially formulated for the Fiberglass Reinforced Plastic (FRP) Industry to clean molds and relieve the problems of wax build-up & over-spray from mold surfaces.

- Important mold release components of Hi-Low Temp 1000 series waxes are specially blended in this product to liquefy and remove most waxes from the molds.

- Can also be used as an inter-phase item for the wax system for prolonged releases and as a cleaner for sharper molds and parts.

- Please note #69 mold cleaner does not relieve Styrene burns.

-

A polymer-based release agent which has high heat stability. It’s polymers provide multiple releases and protection from high heat generated from accelerated exothermic reactions. It is specially designed for:

- Accelerated Exothermic Resins up to 400º F or 204º C

- Multiple Releases

- Compression Molding

- Vacuum Bagging

- Resin Transfer Molding (RTM)